Engineering & Design Services

Sulfur Recovery

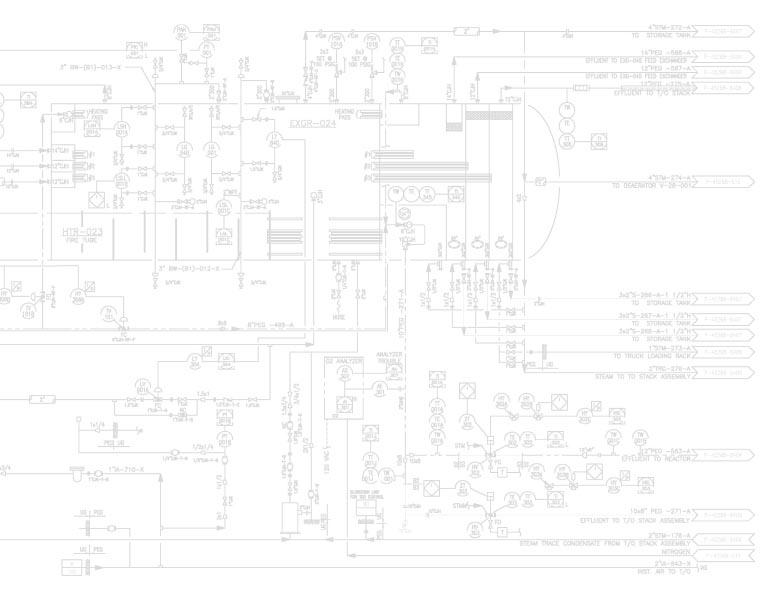

Principal Technology has 25 years of experience designing and building systems to remove and recover sulfur from process streams. Our Sulfur portfolio includes all units in the Sulfur Block - Amine Treating and Regeneration, Sour Water Strippers, Sulfur Recovery, Tail Gas Treating, Thermal Oxidizers and Incinerators, Sulfur Degassing, and Oxygen Enrichment. Our experience ranges from front-end engineering, operations support and training through Turn-key EPC of plants ranging in nameplate capacity from 2 LTPD to multi-train 1000+ LTPD facilities.

get in touch

Sulfur is the fifth most common element by mass on Earth. If something comes out of the ground, it probably has sulfur in it.

Our engineering, design, controls, and fabrication staff have designed and built sulfur units for over two decades. Proper design and fabrication of sulfur processing and handling equipment takes unique experience and know-how.

Principal Technology provides expert solutions for sulfur recovery. We specialize in open-art and proprietary unit designs, tailored specialty equipment, and controls for all of the traditional sulfur block process units, including Amine Treating and Regeneration, Sour Water Treatment, Sulfur Recovery, Tail Gas Treating, Thermal Oxidizers, Sulfur Handling and Degassing, and Oxygen Enrichment units.

related expertise

Engineering Consulting Services

Being a trusted advisor to our clients is a cornerstone of our mission to provide valued engineering solutions. We cannot solve every problem, but our commitment to our clients is to understand their unique challenges and deliver independent technical advice and support.

learn more

Process & Mechanical Engineering Services

The Process and Mechanical Engineers at Principal Technology have decades of experience in process design, equipment design, and troubleshooting for industrial, manufacturing, petroleum, and energy clients. We can help design your process and equipment, rate existing units, troubleshoot and optimize current operations, and train your operators. Whether it is bringing to life an idea from the back of a napkin or expanding existing units, our engineers can find the right solution for your process.

learn more

Planning, Design, & Modeling

Planning to expand existing facilities, add a new modular process unit, or install skid-mounted packaged equipment comes with unique design challenges... Meeting these challenges while providing ergonomic access for operations and equipment maintenance through the entire operating life of a project is where our designers earn their pay.

learn more

Instrument & Control Systems Engineering

Advanced instrumentation and control system design is a critical element of our mission to provide efficient engineering solutions.

learn more

Electrical Engineering Services

The electrical engineers at Principal Technology have years of experience working on heavy commercial, industrial, and manufacturing projects. Our electrical engineers can provide engineering expertise to support your project design, permitting, construction, and operations, from new installations and facility expansions to performance, power, and safety studies.

learn more

Prototyping Services

As an engineer or designer who likes to see your work come to life, Prototype and Proof-of-Concept projects are just plain fun!

PTI's multiple discipline-technical expertise and professional experience have afforded us the pleasure of working on numerous prototype and proof-of-concept development projects.

learn more

Operations Support Services

From process performance evaluation to modernizing legacy equipment, our process, controls, and electrical engineers help clients improve process system performance, extend the working life of your equipment assets, and maintain compliance with current safety standards.

learn more

Training Services

Teach, Show, Do, Review, and Apply... (We didn't invent it, but we use it).

Meaningful training is the cornerstone of our successful projects. Whether it is a basic control system that is new to your operations, a critical process safety or combustion management system, or a large operating plant... Principal Technology engineers are committed to the successful operation of any system we provide our customers - for the life of the equipment!

learn more

our work

Amine Treating and Regeneration

Our knowledge and experience with various types of amine in different applications allow us to select the appropriate amine, strength, and circulation rate to provide optimum equipment design and cost for your application.

The reliable and stable operation of a plant’s Sulfur Plant usually starts with the Amine Unit. Correctly sized low-pressure Rich Amine Flash Drums, well-designed filtration, and reliable Amine Regenerator controls are just a few of our design standards that help our units operate reliably.

read more

Small Capacity Sulfur Recovery

A change in domestic crude feedstocks and increasingly stringent state and federal environmental regulations have raised the demand for small capacity Sulfur Recovery Units in a broader range of process plants.

Principal Technology specializes in turn-key modular units from under 2 to 50 LTPD, affording us unique experience and capabilities to address specific issues of small capacity sulfur recovery, including Heat Conservation, Temperature Management, and Equipment Design to meet the particular needs of small capacity operations while reducing overall cost.

read more

Sour Water Stripping

Sour water units usually see a little bit of everything that runs through a plant. Principal Technology has the knowledge and experience to provide the right solution for your application, from direct steam injection to reboiler units with pump-around condensing.

Correctly sized sour water storage and stripping unit equipment design, Principal Technology can reduce utility usage and optimize capital cost while meeting your plant’s required stripped water composition.

read more