Engineering & Design Services

Training Services

Teach, Show, Do, Review, and Apply...

(We didn't invent it, but we use it).

Meaningful training is the cornerstone of our successful projects. Whether it is a basic control system that is new to your operations, a critical process safety or combustion management system, or a large operating plant... Principal Technology engineers are committed to the successful operation of any system we provide our customers - for the life of the equipment!

get in touch

Our training portfolio helps to empower operators with the knowledge, skill, and confidence to execute their job functions effectively. From process operators to maintenance staff, we tailor the training to meet the specific requirements of your process and equipment.

Our training services cover vital topics such as process hazards, unit operating principles, and real-world troubleshooting challenges. We tailored role-specific training and curriculum material to meet the needs of your specific project.

One key element to any comprehensive training program is to help operations and maintenance personnel understand the hazards inherent within the unit to empower them with the knowledge to identify and rectify problems quickly and safely.

Through our training programs, we strive to not only provide an understanding of critical operational parameters to help them handle excursions and upset conditions but also to understand the plant Design Operating Envelop. We want your operators to know how even small excursions that are seemingly insignificant today can cause long-term performance problems with the unit.

related expertise

Engineering Consulting Services

Being a trusted advisor to our clients is a cornerstone of our mission to provide valued engineering solutions. We cannot solve every problem, but our commitment to our clients is to understand their unique challenges and deliver independent technical advice and support.

learn more

Process & Mechanical Engineering Services

The Process and Mechanical Engineers at Principal Technology have decades of experience in process design, equipment design, and troubleshooting for industrial, manufacturing, petroleum, and energy clients. We can help design your process and equipment, rate existing units, troubleshoot and optimize current operations, and train your operators. Whether it is bringing to life an idea from the back of a napkin or expanding existing units, our engineers can find the right solution for your process.

learn more

Planning, Design, & Modeling

Planning to expand existing facilities, add a new modular process unit, or install skid-mounted packaged equipment comes with unique design challenges... Meeting these challenges while providing ergonomic access for operations and equipment maintenance through the entire operating life of a project is where our designers earn their pay.

learn more

Instrument & Control Systems Engineering

Advanced instrumentation and control system design is a critical element of our mission to provide efficient engineering solutions.

learn more

Electrical Engineering Services

The electrical engineers at Principal Technology have years of experience working on heavy commercial, industrial, and manufacturing projects. Our electrical engineers can provide engineering expertise to support your project design, permitting, construction, and operations, from new installations and facility expansions to performance, power, and safety studies.

learn more

Prototyping Services

As an engineer or designer who likes to see your work come to life, Prototype and Proof-of-Concept projects are just plain fun!

PTI's multiple discipline-technical expertise and professional experience have afforded us the pleasure of working on numerous prototype and proof-of-concept development projects.

learn more

Operations Support Services

From process performance evaluation to modernizing legacy equipment, our process, controls, and electrical engineers help clients improve process system performance, extend the working life of your equipment assets, and maintain compliance with current safety standards.

learn more

Sulfur Recovery

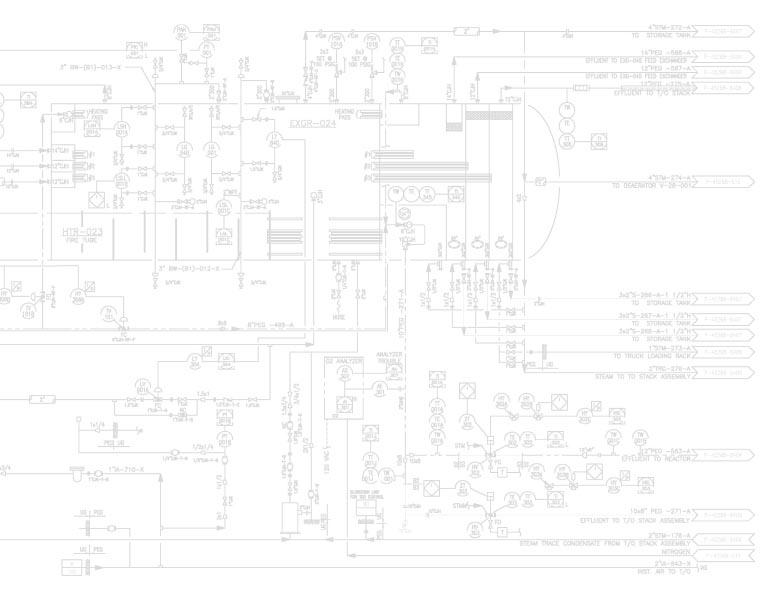

Principal Technology has 25 years of experience designing and building systems to remove and recover sulfur from process streams. Our Sulfur portfolio includes all units in the Sulfur Block - Amine Treating and Regeneration, Sour Water Strippers, Sulfur Recovery, Tail Gas Treating, Thermal Oxidizers and Incinerators, Sulfur Degassing, and Oxygen Enrichment. Our experience ranges from front-end engineering, operations support and training through Turn-key EPC of plants ranging in nameplate capacity from 2 LTPD to multi-train 1000+ LTPD facilities.

learn more

our work

Sulfur Recovery Unit Training

Sulfur Recovery Units are a vital emissions reduction unit in many petroleum and gas treating plants. PTI process engineers have decades of experience designing, building, and providing operations support for SRUs.

We provide operator training to keep your unit operating efficiently. As importantly, we focus our training on practical theory to help your operators understand how minor adjustments today will keep the unit operating at peak performance tomorrow.

read more

Water System SCADA Control Upgrade

Technology upgrades on legacy infrastructure can also provide a unique training opportunity for project stakeholders.

Principal Technology enjoyed working on this project to migrate a municipality water system from a legacy radio network SCADA system to a Cloud Hosted SCADA-as-a-Service platform. Our controls engineers provided hands-on training for the town’s water operations staff. Helping the operators gain confidence with the new system and its historical data capabilities provided an immediate improvement in how they operate the system by bridging the data flow between plants.

read more